Two component room temperature cured epoxy resin AB adhesive 830

Product model: SD830 epoxy resin AB adhesive

Characteristics: This product is an impact resistant epoxy AB adhesive. Strong universality, fast curing speed, low curing heat, impact resistance, resistance to most chemical media, and excellent electrical insulation performance. Structural bonding of materials such as glass to glass, glass to metal, metal to metal, metal to plastic, plastic to plastic, etc; Use PE/PP/PET or flexible plastic materials with caution.

Environmental requirements: Comply with RoHS directives and related environmental requirements

Reference standard: SAE AMS 3690C-2009 room temperature cured epoxy resin composite adhesive.

Main Characteristics of Two Component Room Temperature Curing Epoxy Resin AB Adhesive

1. Two component 1:1, low viscosity, easy to self level.

2. Surface drying time: 25-30 minutes, initial solidification time: 1-2 hours.

3. Solvent free, low shrinkage, repairable, smoke-free gel.

4. It has good insulation, vibration resistance, impact resistance, peel resistance, and other properties.

5. Good adhesion and fixation of materials such as metal, plastic, rubber, glass, etc.

Two component room temperature cured epoxy resin AB adhesive is mainly used in mechanical and electrical machinery, aviation, stone, home decoration, glass, ceramics, jade, handicrafts, metal and vulcanized rubber, electronic transformers, smart meters, sensors, monitors, aluminum grids, waterproof connectors, radiation detectors, thermometers, inductors, cameras, meters, etc. It is a necessary helper for professional repair.

Method of use for two-component room temperature cured epoxy resin AB adhesive

1. The surface of the adhesive should be kept clean and dry, and metal objects should be cleaned with acetone or other solvents.

2. Mix and stir the A/B components in a 1:1 ratio and evenly apply them to the surface of the adhesive.

3. The mixed gel is used up within 2 minutes, and the gel automatically solidifies after a timeout. It solidifies for 30 minutes at room temperature and reaches its optimal strength within 12 hours.

Complies with GB33372-2020 (VOC) volatile organic compound certification, REACH EU testing standards, and the enterprise has passed UL certification for flame retardancy grade E358706, ISO14001:2015 certification, ISO9001:2015 certification. The cited standard is HG/T3947-2007 single component room temperature vulcanization silicone adhesive/sealant, and is a national high-tech enterprise. Our products have passed 1000 hours of cold and hot impact testing, 1000 hours of dual 85 (high temperature and humidity) testing, and 1000 hours of high temperature aging testing, committed to providing reliable thermal conductivity solutions for industries such as automobiles, communication, and security.

application

Suitable for bonding of metals, electroplating/baking materials, ceramics, glass, and exquisite craftsmanship.

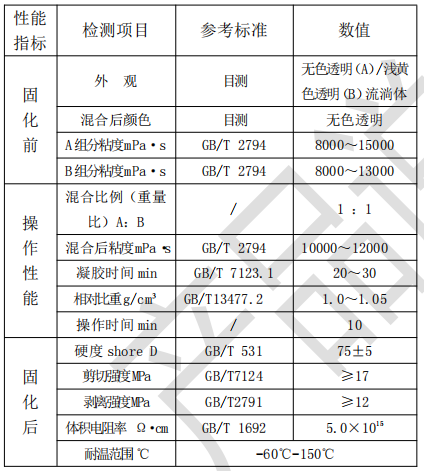

Technical parameters (At TA=25 ℃)

Usage and precautions

Weighing: Accurately weigh components A and B, and mix them thoroughly in a 1:1 (mass) ratio. Before weighing, separate components A and B should be stirred evenly to evenly disperse the settled filler into the gel, in order to avoid affecting the colloidal properties.

Mixing: Use manual or machine mixing to thoroughly and evenly mix the rubber material, so that the rubber material has a uniform color. When using manual glue filling process, it is important to note that the one-time amount of glue should not be too much to avoid difficulty in glue filling due to reduced fluidity in the later stage.

Curing: The adhesive after coating should be immediately assembled and tightly clamped, and uniform contact pressure will ensure maximum bonding strength. To achieve the highest mechanical strength, the material surface can be polished or sandblasted, and then the surface dust and oil stains can be wiped with a special solvent. It is necessary to apply adhesive on both sides of the bonding area, and then fix the bonding area to avoid misalignment. Do not cross the covers of AB and AB, and do not pour the removed glue back into the original container to prevent contamination of the original glue.

Precautions for two-component room temperature cured epoxy resin AB adhesive

This product is not a hazardous material, but do not enter or eye contact.

This product has a slightly irritating odor. Please wear a gas mask and anti-corrosion gloves when operating.

Cover at any time after each material collection to avoid moisture absorption affecting curing and performance.

Store in a cool and dry environment that is not easily accessible to children. When using this product in large quantities, it is necessary to use it in a well ventilated area.

If it accidentally gets on the skin, please wash it immediately with soap and water.

If it accidentally gets into your eyes, please rinse thoroughly with plenty of water and seek medical attention immediately.

Packaging, storage and transportation requirements

Transportation: There are no regulations in China (CN-GB) or internationally (IMO, IATA, UN). It belongs to non hazardous goods.

Two component room temperature curing epoxy resin AB adhesive packaging

① The packaging of materials has a certain protective and sealing effect on the materials, ensuring that they are not damaged during transportation.

② The packaging box should have product model, name, quantity, manufacturer's trademark, production batch, and other information.

③ The packaging box should meet the requirements of moisture resistance, shock resistance, pressure resistance, and mold resistance.

Storage: Products packaged in boxes should be stored in a cool and dry environment with an ambient temperature below 26 ℃. The surrounding air should be free of acidic, alkaline, or other corrosive gases. Under these conditions, the product can be stored for six months from the production date, and the material remains qualified within these six months.

Packaging specifications: AB group 2kg, AB group 64g

Declaration of Two Component Room Temperature Curing Epoxy Resin AB Adhesive

Users must carefully read the relevant information of this product before using it. Users are responsible for conducting comprehensive tests based on their respective uses to confirm its performance, effectiveness, safety, etc.

Our company denies any other expressed or implied warranties. If your company fails to conduct corresponding performance tests and directly uses the product, resulting in unqualified products, our company and the intermediary sales legal person shall not bear any responsibility. We hereby declare!

Product description

SD830 is a two component room temperature curing epoxy resin adhesive used for room temperature or low temperature curing. After curing, the adhesive layer has a medium hardness, which can withstand extremely strong impacts and vibrations. The adhesive layer has good mechanical properties and electrical insulation, can withstand temperature changes and bending tear stress, and is non corrosive.

Application industries: digital electronics, office equipment, instruments, communication equipment, security equipment, electric tools

Key words:

Related products

undefined

Get free product quotes

Mobile website

SANDAO

400-066-0768

TEL: 0752-6822862 682668251

ADD:Yanjiang Road, Zhouliao Zai Industrial Zone, Boluo Garden, Huizhou City

copyright © 2023 Huizhou Sandao New Material Co., LTD All rights reserved.