Acrylate AB structural adhesive, two component structural adhesive SD823

Characteristics: The third generation acrylic structural adhesive is suitable for the bonding of metals, plastics, and composite materials; The ratio of main agent to curing agent is 10:1, which has the characteristics of simple operation, fast curing speed, and high strength; The cured product has characteristics of impact resistance, fatigue resistance, and high frequency vibration resistance. The product can pass RoHS certification and meet export requirements to the European Union. Acrylate AB structural adhesive, also known as composite cold solder, is a 10:1 two component MMA product with a viscosity of around 70000 cps after mixing. Its surface dries quickly, overflow is easy to control, and its toughness is good. Bonding metal does not require primer or surface treatment.

main features

1. AB two component 10:1, modified acrylate adhesive

2. Suitable for bonding between the same or different materials such as metals, plastics, ceramics, etc

3. Excellent temperature resistance, seismic resistance, and high-strength adhesive strength

4. Solid content 100%, environmentally friendly solvent-free

5. Rapid curing, initial solidification in 5 minutes, reaching 80% strength in 30 minutes

Mainly used in: tire pressure sensors, photoelectric sensors, laptop casings, tablet computer casings, robots, monitors, LED displays

application

Mainly used for bonding materials such as metals, aluminum magnesium alloys, anodized aluminum, stainless steel, engineering plastics, composite materials, ceramics, glass, ABS, PC, PMMA, carbon steel, etc.

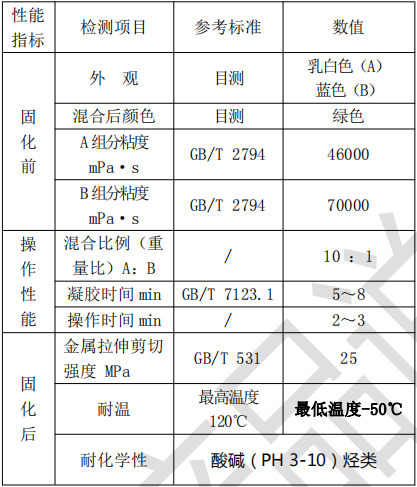

Technical parameters (At TA=25 ℃)

Usage and precautions

This product is flammable. Please store or use it away from flames, high heat, and sparks. This product contains methacrylic acid and should be kept out of reach of children. Please cover and place after use. Try to avoid skin and eye contact. If you accidentally come into contact with the skin, wash it with soap as soon as possible. After contact with the eyes, rinse with plenty of water for 15 minutes and seek medical attention as soon as possible. This product is not edible. Please refer to the Material Safety Data Sheet for details. Additionally, due to the rapid solidification of this product, a large amount of heat is generated during mixing, which may be accompanied by the release of volatile substances such as gases and vapors. Therefore, each mixing should be limited to the amount that can be used up within the operating time, and the bonding thickness should be controlled within 0.95cm. For operational application issues, please contact our company directly.

Operation&Cleaning

To achieve optimal bonding strength, bonding must be completed within the selected adhesive operation time. A sufficient amount of adhesive should be selected to ensure that the joints are fully filled. Before the end of the operation time, it is necessary to accurately complete the adhesive application and object positioning work, and then maintain the fixed state of the object until the curing time is over before removing it. The residual adhesive on the edge before curing is easy to clean, and can be wiped with a detergent or degreaser containing citric acid terpene resin or NMP to achieve the best effect; If the adhesive layer has solidified, carefully hang it off and scrub it with a glue remover to achieve a perfect effect.

note

This product is flammable. Please store or use it away from flames, high heat, and sparks.

This product contains methacrylic acid and should be kept out of reach of children. Please cover and place after use. Try to avoid skin and eye contact. If you accidentally come into contact with the skin, wash it with soap as soon as possible. After contact with the eyes, rinse with plenty of water for 15 minutes and seek medical attention as soon as possible. This product is not edible. Please refer to the Material Safety Data Sheet for details. Additionally, due to the rapid solidification of this product, a large amount of heat is generated during mixing, which may be accompanied by the release of volatile substances such as gases and vapors. Therefore, each mixing should be limited to the amount that can be used up within the operating time, and the bonding thickness should be controlled within 0.95cm. For operational application issues, please contact our company directly.

statement

Users must carefully read the relevant information of this product before using it. Users are responsible for conducting comprehensive tests based on their respective uses to confirm its performance, effectiveness, safety, etc.

Our company denies any other expressed or implied warranties. If your company fails to conduct corresponding performance tests and directly uses the product, resulting in unqualified products, our company and the intermediary sales legal person shall not bear any responsibility. We hereby declare!

Product description

Summary: SD823 is a two component structural adhesive composed of synthetic acrylate and modified curing agent, with both A and B having 100% solid components; Fast curing, high strength, can be initially fixed in about 5 minutes, can reach 80% strength after 30 minutes, and maximum strength after 24 hours; Strong adhesion between metal objects, superior impact strength to epoxy resin, excellent cold and hot resistance, and working temperature of -30~120 ℃.

Mainly used in: tire pressure sensors, photoelectric sensors, laptop casings, tablet computer casings, robots, monitors, LED displays

Key words:

Related products

undefined

Get free product quotes

Mobile website

SANDAO

400-066-0768

TEL: 0752-6822862 682668251

ADD:Yanjiang Road, Zhouliao Zai Industrial Zone, Boluo Garden, Huizhou City

copyright © 2023 Huizhou Sandao New Material Co., LTD All rights reserved.